Cold Roof Prepainted Steel Coil

Category:

Keywords:

Cold Roof Prepainted Steel Coil

Details

Product Description

The "Cold Roof" series of color steel products are high quality color steel products produced with AkzoNobel's "Cold Chemical" coating. This product adopts heat-reflective coating to make the color-coated panels absorb visible light and reflect heat at the same time, thus keeping the room cool, reducing energy consumption during the peak of electricity consumption in summer, reducing pollution and protecting the environment. On top of ensuring excellent color permanence, high weather resistance and other characteristics, it adds an increase in excellent energy-saving performance. It meets the requirements of LEED and ENERGY STAR, and is the best solution for energy-friendly coatings.

Material Selection

National enterprise base material, Akzo heat reflective coating

Technical Conditions

Hot-dip galvanized Z100(+) Aluminized zinc AZ80(+), front film thickness: 5+20u, back: 5-7u

Standard specification

Hot-dipped galvanized steel coil, galvanized weight Z100g/m2 according to GB/T2518-2008.

Adopt hot dip galvanized 55% aluminum zinc steel coil, the weight of zinc layer is AZ80g/m2 according to GB/T14978-2008

Product performance

Salt spray resistance test: ≥2000 hours without rust spots and obvious discoloration, blistering (GB13448-20061); - double-sided with acid and alkali test; GBT13448-2006); - acid resistance 5% HCL: diffuse bubble 120 hours without bubbles: - alkali resistance 5% NaOH diffuse bubble 120 hours without bubbles.

Top coat UV aging test: ≥ 2000 hours, color difference ≤ 6, gloss retention rate of 50% no rust, blistering, cracking no chalking (GB/T13448-2006)

Recommended use

High-grade buildings or landmark buildings

Product characteristics

Meets the requirements of LEED® and U.S. Energy Star, and is the best solution for energy-friendly coatings.

Advantage:

◆ Annual output 640,000 tons

◆ Quality assurance 10 years

◆ 20 + years of experience in the steel industry

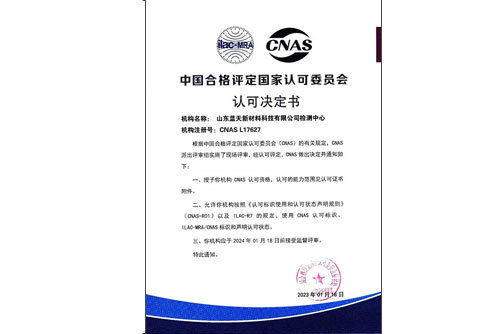

◆ CNAS National Laboratory

Real experimental data:

Test requirements: 5% acid ≥ 8H 5% alkali ≥ 24H salt spray ≥ 500H UVA-340 ≥ 1000H T bend ≤ 3T MEK ≥ 80 times

SCZM substrate AZ80 substrate and front 5 + 15μm film thickness.

The beauty of silk: Aksu crimson acid-resistant state for 10 hours

Beauty of Silk: Aksu White Acid Resistance Test 10 Hours State Light

The beauty of silk: white gray alkali resistance test 105 hours state

The beauty of silk: sea blue alkali resistance test 105 hours state

Beauty of Silk: Sea Blue UVA Test 1380 Hours State

The beauty of silk: white gray UVA test 1380 hours state

The beauty of silk: white gray acid resistance test 12 hours state

The beauty of silk: sea blue acid resistance test 12 hours state

Packing & Transportation

Packing Details: wooden boxes package, pvc package and other standard seaworthy package.

Transportation: Sea transportation, railway transportation, etc

Leave A Message