Sandwich Panel

Category:

Keywords:

Sandwich Panel

Details

Heat-insulating sandwich panel composite production line is a new type of building material with high strength, light weight, strong and durable, and beautiful appearance by laminating the book high strength material on the single and double-sided outer layer of thicker and lighter inner core material. Generally the outer layer is made of 0.3-0.6mm color steel plate, but also stainless steel plate, aluminum plate, plastic plate and other materials. The inner core is made of thicker and lighter materials such as EPS spontaneous self-extinguishing polyurethane, foamed polyurethane and other fire-resistant core materials such as glass wool, and the thickness is between 50-300mm, which can be chosen arbitrarily. It can be used in public buildings, industrial plants, large warehouses, large-span roofs, walls, cold storage, purification rooms, air conditioning rooms and other places. Because of its light weight (equivalent to 40-60 molecules of ordinary bricks), high strength, beautiful appearance, convenient construction and short construction period, it has become one of the more ideal new building materials in today's building materials industry and is widely used.

The whole line process flow

---Unwinding ---Laminating (flat cutting) ---Plate forming ---Plate preheating (rock wool stacking feeding ---Lifting ---Splitting and cutting (vacuuming) ---90°Flip ---Whole row ---Rock wool spraying glue ---Side foam) ---PU high pressure foam ---Double track compound forming ---Bandsaw cutting ---Fast rollerway ---Cooling and drying board ---Stacking --- Packing

Corrugated Composite Panel

(1) Lapped corrugated laminate

Advantage:

◆ Annual output 640,000 tons

◆ Quality assurance 10 years

◆ 20 + years of experience in the steel industry

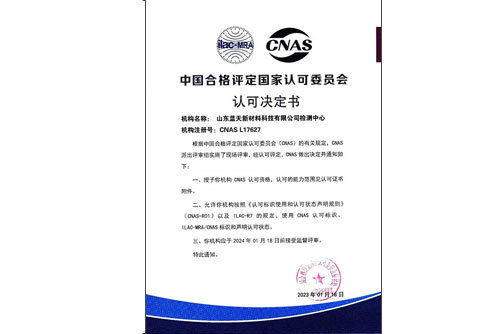

◆ CNAS National Laboratory

Real experimental data:

Test requirements: 5% acid ≥ 8H 5% alkali ≥ 24H salt spray ≥ 500H UVA-340 ≥ 1000H T bend ≤ 3T MEK ≥ 80 times

SCZM substrate AZ80 substrate and front 5 + 15μm film thickness.

The beauty of silk: Aksu crimson acid-resistant state for 10 hours

Beauty of Silk: Aksu White Acid Resistance Test 10 Hours State Light

The beauty of silk: white gray alkali resistance test 105 hours state

The beauty of silk: sea blue alkali resistance test 105 hours state

Beauty of Silk: Sea Blue UVA Test 1380 Hours State

The beauty of silk: white gray UVA test 1380 hours state

The beauty of silk: white gray acid resistance test 12 hours state

The beauty of silk: sea blue acid resistance test 12 hours state

Packing & Transportation

Packing Details: wooden boxes package, pvc package and other standard seaworthy package.

Transportation: Sea transportation, railway transportation, etc

Leave A Message