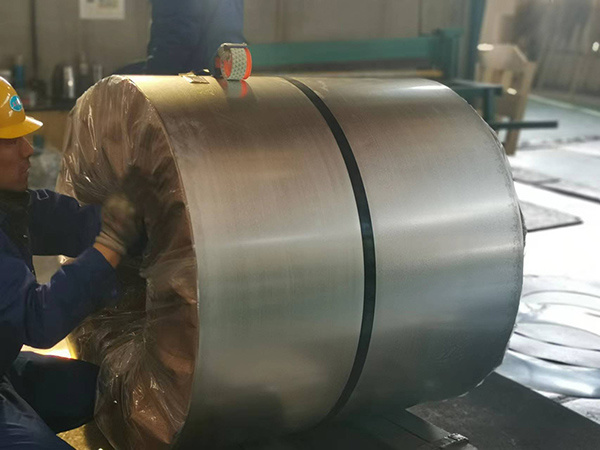

Hot-dip Galvanized Steel Coil

Category:

Keywords:

Hot-dip Galvanized Steel Coil

Details

The substrates of galvanized/galvalume steel sheets adopt stable SBT texturing techologywhich not only effectively improves the adhesion of color coated steel sheetbut also greatly improves the beauty and mach-inability of sheet surface.

Product Specifications

|

Product Name |

Galvanized Steel Sheet/Galvalume Steel Sheet |

|

Material |

Dx51D, Dx52D, Dx53D |

|

Thickness |

0.12-6.00mm or customer's requirement |

|

Width |

600mm-1500mm, according to customer's requirement |

|

Zinc coated |

30g-100g/m2 |

|

Type of Coating |

Hot Dipped Galvanized Steel |

|

Surface Treatment |

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

|

Surface Structure |

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

|

Coil ID |

508mm or 610mm |

|

Coil Weight |

3-10 metric ton per coil |

|

Standard |

JIS 3302 / ASTM A653 /EN10143 AISI , ASTM , DIN , GB , JIS G3302 G3312 G3321 , BS |

|

Origin |

Shandong China |

|

Certificates |

ISO9001-2008 |

|

Delivery Time |

Usually within 10-30 days after receipt of advance payment |

Main features.

★Excellent cold-rolled steel strip as the base material, excellent processing performance, good stamping resistance.

★Uniform thickness of zinc layer, strong adhesion, processing and forming without peeling, good corrosion resistance.

★Glossy surface, precise size, straight plate, uniform and beautiful zinc flower.

★After passivation, oiling treatment, no deterioration in short-term storage in the warehouse.

★After surface polishing, it is a good substrate for making anti-corrosion coated plates.

High salt spray resistance

Neutral salt spray resistance test of LANYUNboutique ≥600H(national standard 480h) Super strong anti-aging

LANYUNUVA-340 anti-aging test is more than 1000H(GB 600H)

Advantage:

◆ Annual

output 640,000

tons

◆

Quality assurance 10

years

◆ 20 +

years of experience in the steel industry

◆ CNAS

National Laboratory

Real experimental data:

Test

requirements: 5% acid ≥ 8H 5% alkali ≥

24H salt spray ≥ 500H UVA-340 ≥ 1000H T bend ≤ 3T MEK ≥

80 times

SCZM substrate AZ80 substrate and front 5 + 15μm film

thickness.

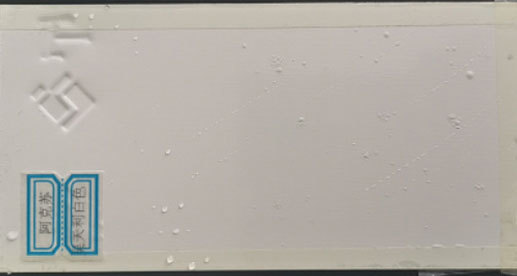

The beauty of silk: Aksu crimson acid-resistant state for 10 hours

Beauty of Silk: Aksu White Acid Resistance Test 10 Hours State Light

The beauty of silk: white gray alkali resistance test 105 hours state

The beauty of silk: sea blue alkali resistance test 105 hours state

Beauty of Silk: Sea Blue UVA Test 1380 Hours State

The beauty of silk: white gray UVA test 1380 hours state

The beauty of silk: white gray acid resistance test 12 hours state

The beauty of silk: sea blue acid resistance test 12 hours state

Packing & Transportation

Packing Details: wooden

boxes package, pvc package and other standard seaworthy

package.

Transportation: Sea transportation, railway

transportation, etc

Leave A Message